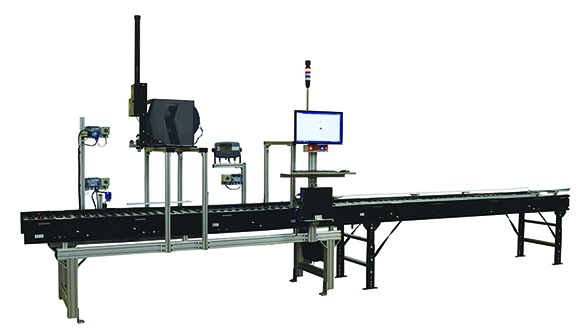

Walz SPRINTER Shipping System

Automated Shipping & Manifesting System

Walz Label and Mailing Systems SPRINTER Shipping System with automatic shipping and manifesting with quick implementation based on a pre-engineered approach. This is a robot that works without errors, breaks or overtime.

Our revolutionary design starts on-demand. It reads, weighs, and cubes, processes, labels and verifies the parcel. System status is intuitive for both the operator located at the machine, as well as from across the warehouse via optional tower light display. Increased throughput and the efficient use of manpower will dramatically change your warehouse.

|

SPRINTER will ID the order from a bar code on the side of the parcel, capture the weight from a scale, dimension, and communicate with your ERP or existing multi-carrier system. Pre-engineered interfaces including Pro-Ship™, as well as directly to FedEx and UPS.

SPRINTER applies the carrier-compliant shipping label and redundantly verifies it for accuracy; no case passes through without a successful check. Throughput is typically 600 - 1000 cases per hour. Higher throughput systems up to 4,000 cases per hour available.

Each SPRINTER shipping system can be custom designed for your unique application in the warehouse.

|

Simple Operation

Built with the fast pace of the warehouse industry in mind, all parameters can be remotely monitored and configured with an internet connection; no VPN is required. Scanners include memory modules so configurations are auto-loaded into a new device.

|

Implementation is a breeze. SPRINTER rolls into place and a single-point 120VAC electrical connection (grounded plug) is all that is needed. The system is inherently safe using low voltage and low forces.

Top performance, user friendly interface and pricing like no other shipping system on the market today.

Walz SPRINTER Shipping System

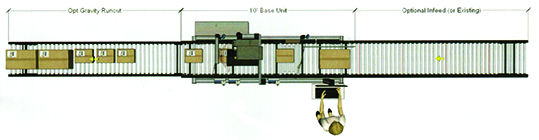

Walz provides turnkey shipping solutions for single carrier, multi-carrier, and multi-line systems.

HIGHLIGHTS:

- Increase throughput

- Save floor space

- Verify & log every package

- Beat carrier cutoff times

- Rate shop carriers

- Eliminate human errors

- Manage Dimweight charges

- Integrate with existing conveyor

- Consolidate metering stations

- Multi-level security

- Data logging

- Customized host interfaces

- Carrier sortation

- Rich exception messaging

- Parcel lookup and search

- Productivity metrics

- Optional major carrier interfaces

SPECIFICATIONS:

- Dimensions (LxWxH): 120" x 42" x 80"

- Conveyor Scale: 22" effective width

- Box size (LxWxH) 9" x 6" x 1" minimum and 28" x 20" x 20" maximum

- Weighing Capacity: .02 lbs. minimum and 75 lbs. maximum

- Weighing Division: .02 lbs.

- ID Code Requirement: 20 Mil, ANSI B or better Code 128

- System Throughput: 600 - 1000 cases per hour with optional 4000 cases/hr. system

- Right Hand Flow standard or left hand flow available at no additional cost

Multi-Carrier Shipping

Are you a rate shopper using ClipperShip, ProShip, Pitney Bowes, or other rate shopping software? No problem. Both SolidShip™ and SolidLabel™ integrate seamlessly to generate labels, interface the rate shopping software, and verify the shipping label was applied to the intended package.

Shipping Sortation

Downstream functions include multi-carrier sortation based on carrier (FedEx, UPS, etc.), service type (Overnight, Express, Ground, USPS First Class, etc.).